Static Checkweigher: In addition to verifying the weight and directing product flow, a check weighing system also provides valuable statistical information. This information can be used for SPC (Statistical Process Control) to support the requirement for quality records. Usually the check weighing station is an inspection station after the manufacturing or packaging process. By analyzing and feeding back the results of the check weighing operation, the source process can be adjusted to optimize quality and lower costs. Automatic or manual feedback or information is downloaded to a printer, computer or PLC.

In Motion Checkweigher. The in motion check weighers can be utilized for weighing in motion without stopping the supply line to weigh each individual product or package. This reduces labor costs while giving an accurate weight and improving efficiencies. The conveyor can also reject products that are under/over the weight requirements. Can be applied to and product line where a conveyor belt is used to move products through the production chain. These scales are available in both static and in motion conveyor weighing. The in motion check weighers can also grade product and sort fully automated and send the data collected to the managers or decision makers in real time.

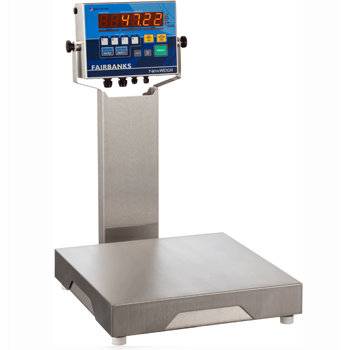

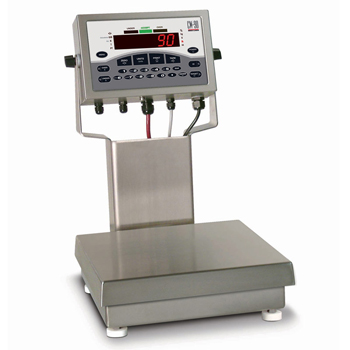

The NexWeigh is Fairbanks Scales new stainless steel multi-function instrument, available in NEMA 4X and IP69K rated enclosures. The NexWeigh is a perfect compliment to Fairbanks Scales stainless steel sanitary design bench scale platforms.

Accessories: Printer, Conveyor extensions, printer/labeler, sorter/grader, food grade conveyor belt.

We offer a variety of checkweighers. Contact our office for more information.

Call Us

Our Staff is ready to provide you with a weighing solution today.

(855) 722-5320Email Us

If you have more detailed needs or prefer to email us.